Welder automation is the simplest way to reduce

production costs, improving your profit margin.

Production efficiencies and process improvements can

be obtained when any repetitive welding task is

performed by a machine. The benefits of automation

extend beyond simply improving speed; automation

also improves consistency, which reduces

rework and improves quality. All of these benefits

(improved production cost, improved quality,

reduced rework, and streamlined processes) equates

to greater customer satisfaction; the foundation of

all successful businesses.

Arc Welders can create customized automation

built around your current production processes and

existing equipment. Contact us to discuss your

production needs.

|

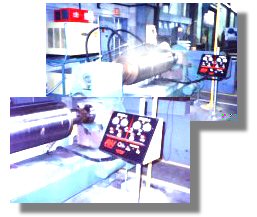

Semi-Automation Case Study

In this case, the customer needed a control box designed to control two systems with fixed MIG

units that weld a cylinder in two spots

simultaneously. This cut production time in half and made cleaner, straighter beads down the cylinder.

By adding to existing equipment, Arc Welders created

an economical package that dramatically improved

production time and quality. In this case, the customer needed a control box designed to control two systems with fixed MIG

units that weld a cylinder in two spots

simultaneously. This cut production time in half and made cleaner, straighter beads down the cylinder.

By adding to existing equipment, Arc Welders created

an economical package that dramatically improved

production time and quality.

|

|